The Role of Wirco's Serpentine Trays for Our Heat-Treating Customers

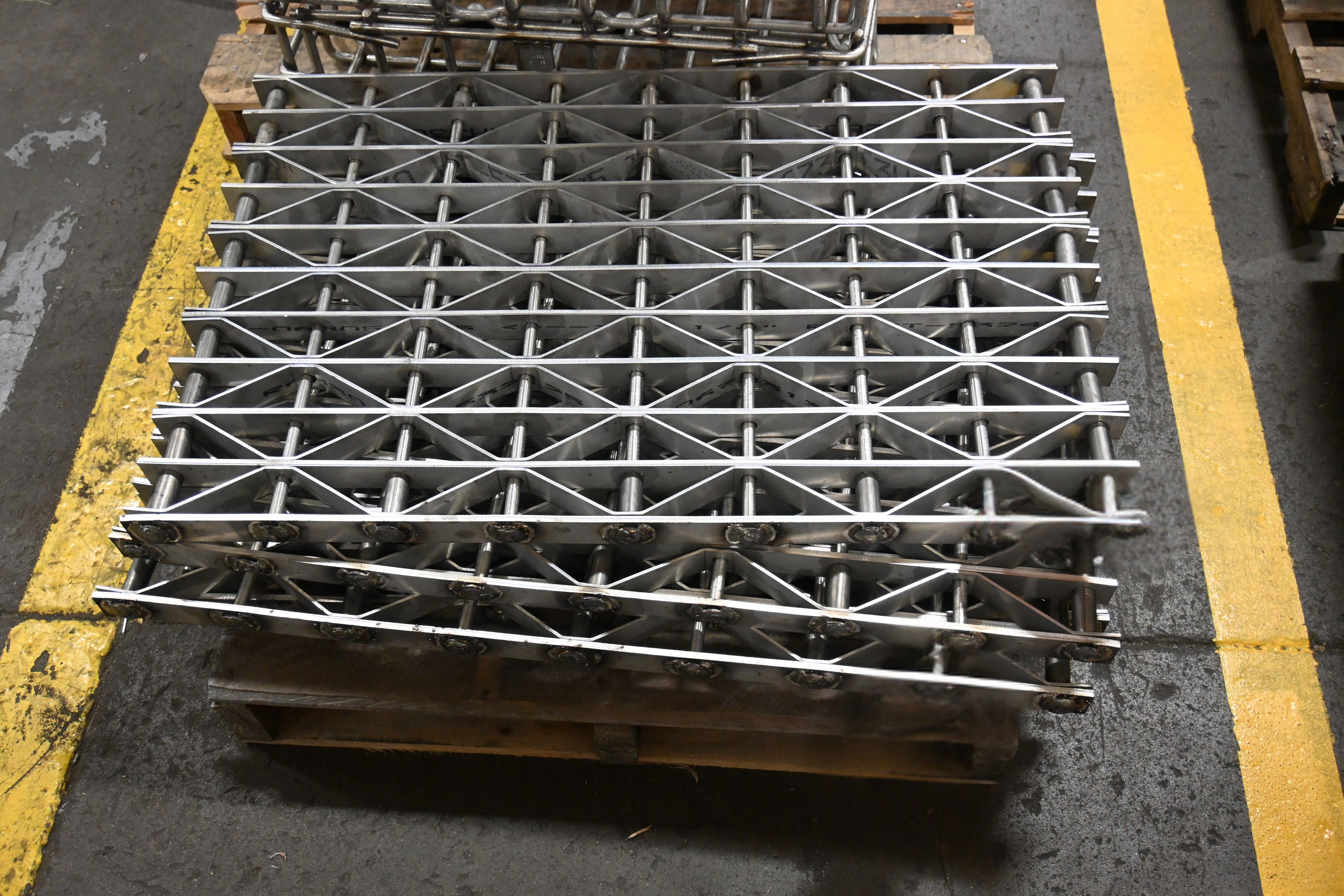

Serpentine trays are heat-resistant alloy fixtures designed with a unique, undulating profile resembling a snake’s movement—hence the name. Their design maximizes load distribution, minimizes warping under intense thermal conditions, and ensures even exposure to heat, making them indispensable in producing components requiring meticulous thermal treatment.

Like our cast furnace trays, serpentine trays are designed to be lightweight but strong enough to hold up to extreme operating temperatures and weights. We routinely produce vacuum furnace applications that handle temperatures above 2200 degrees Fahrenheit. Wirco produces serpentine trays at our Avilla, Indiana campus.

The Benefits of Wirco's Serpentine Trays in Heat Treating

Unmatched Durability: Crafted from advanced heat-resistant alloys, serpentine trays can endure prolonged exposure to high temperatures without succumbing to deformation or degradation. This ensures reliability even in the harshest environments.

Enhanced Efficiency: Our trays promote uniform heat flow around the components being treated. This results in consistent processing, reduced cycle times, and energy savings—critical for industries aiming to streamline operations and cut costs.

Optimized Material Handling: Serpentine trays are designed to securely hold parts in place, reducing the risk of misalignment or damage during the heat treatment process. Their design also assists in easy loading and unloading, further boosting operational efficiency.

Versatility: These trays are suitable for a wide range of applications, from carburizing and nitriding to annealing and tempering. Their adaptability makes them a preferred choice across various industries, including automotive, aerospace, and heavy machinery.

We thank you for your business and hope you consider Wirco for your next alloy purchase