The Role of Heat Exchanger Tubing Bundles in Steel Mills

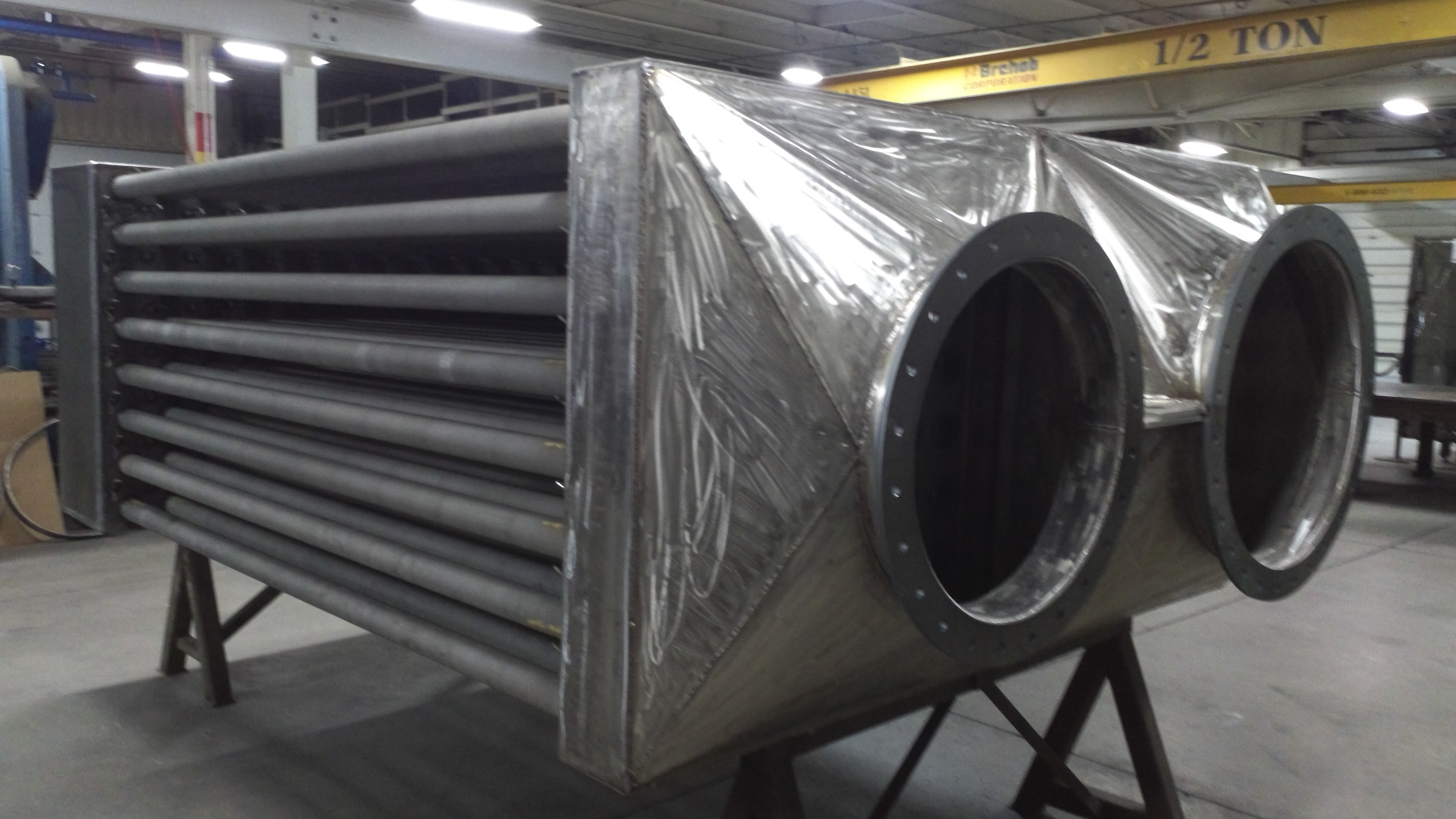

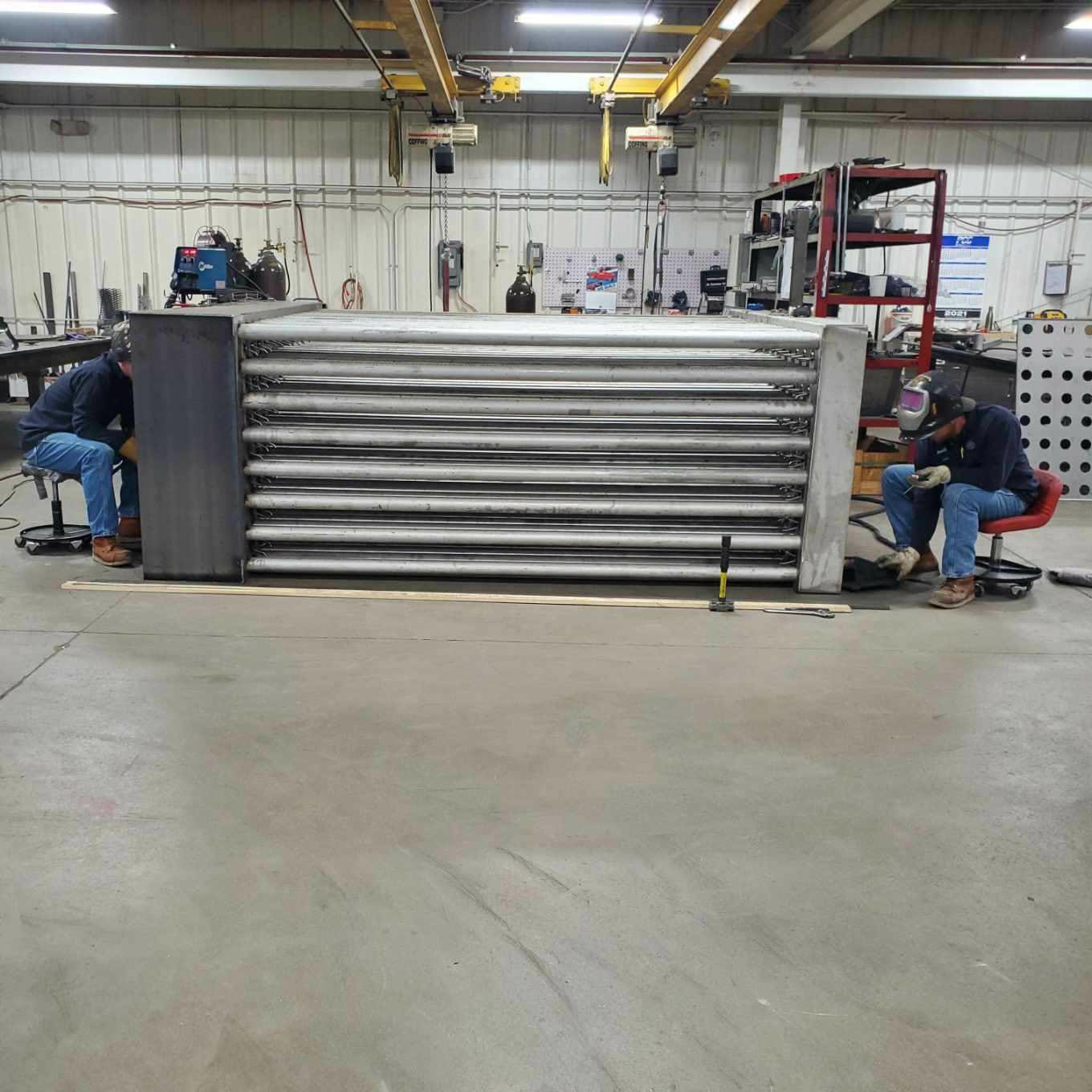

Heat exchanger tubing bundles are integral to many heat recovery systems used in the steel mill industry. These bundles consist of multiple tubes that are tightly packed together, often inside a shell, to facilitate efficient heat exchange between fluids or gases. In a steel mill, they typically function to transfer heat from hot exhaust gases, molten metal, or steam to cooler fluids, such as water or oil.

Heat exchanger tubing bundles serve as a crucial component for:

Energy Recovery: Reclaiming waste heat from flue gases or cooling systems, reducing the need for additional energy consumption.

Temperature Regulation: Ensuring consistent cooling of steel billets, slabs, and other products that require precise temperature control to maintain quality and prevent defects.

Process Efficiency: Providing a reliable heat transfer solution in cooling systems, such as quenching, to avoid thermal damage and improve throughput.

We thank you for your business and hope you consider Wirco for your next alloy purchase.