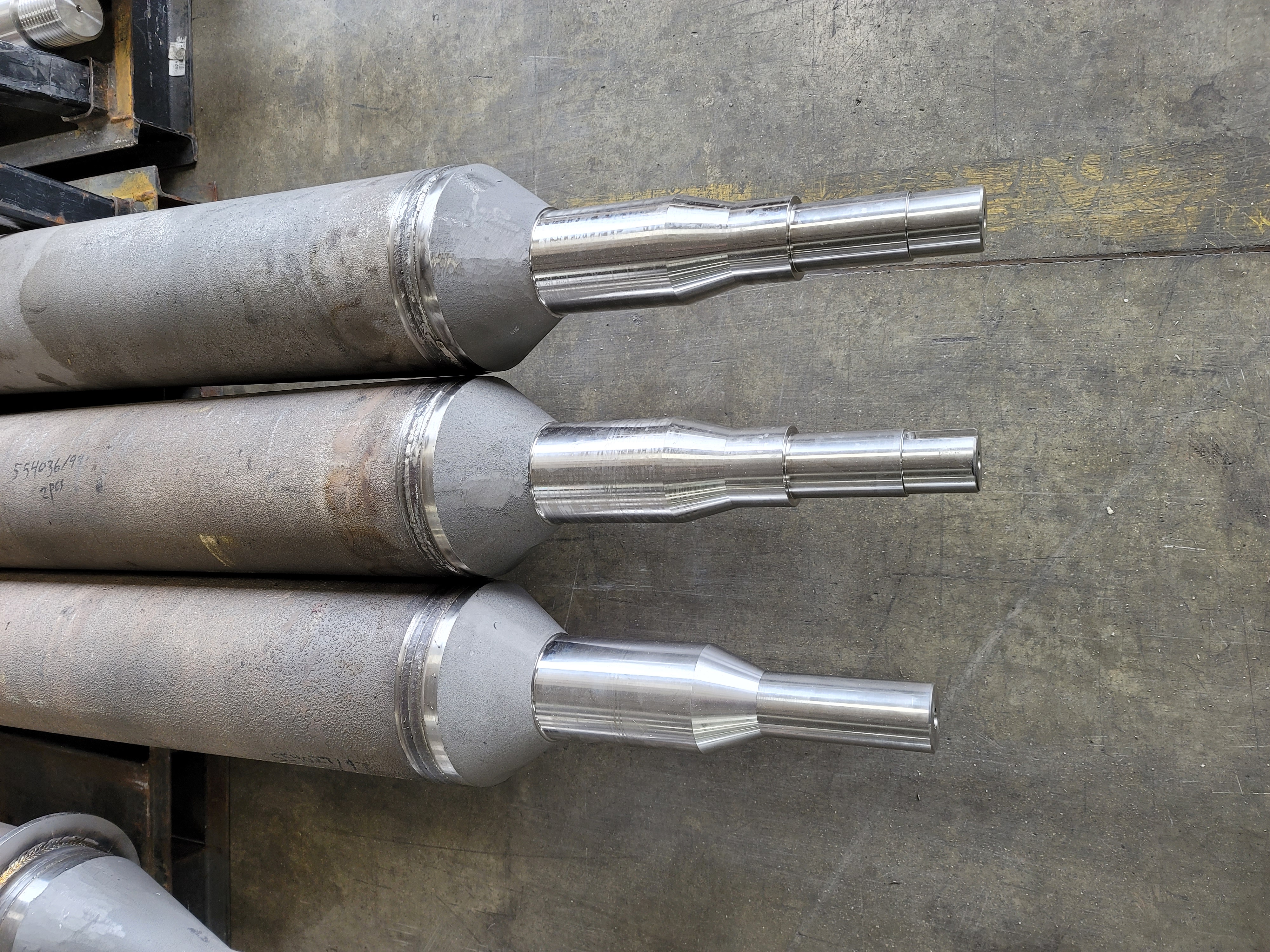

The Importance of Tunnel Rolls in Steel Processing

Tunnel rolls are crucial for several reasons, with each designed to handle specific challenges that arise during steel processing. Their role extends beyond simple movement, influencing several aspects of production, such as:

Moisture Removal: After steel is washed or pickled, moisture is often left on the surface. Tunnel rolls ensure that steel products, whether in coil or sheet form, are moved through the drying tunnel where controlled heat and airflow work together to eliminate residual moisture. This is particularly important for preventing the formation of surface defects such as rust, scaling, or pitting during the drying process.

Smooth and Stable Movement: Tunnel rolls help ensure that steel products are consistently and smoothly transported through the drying tunnel. By applying uniform pressure and support, these rolls prevent misalignment, jamming, or skewing of steel products. This ensures that the steel moves efficiently, maintaining throughput without unnecessary delays or product damage.

Heat Distribution and Temperature Control: During the drying process, temperature control is vital. Tunnel rolls, often in combination with air blowers and heat exchangers, help maintain a uniform temperature across the surface of the steel. This consistency is crucial for preventing thermal stresses that could lead to cracks or defects in the steel, particularly when the material is undergoing high-temperature treatment or tempering.

Surface Quality Control: Maintaining the integrity of the steel’s surface is essential, especially in high-value applications where surface finish is paramount. Tunnel rolls help prevent any abrasions, marks, or contaminants from coming into contact with the steel’s surface. By ensuring smooth and even handling, they help maintain the high-quality finish that the final product demands.

The Benefits of Using Wirco's Tunnel Rolls in Steel Mills

Enhanced Product Quality: By maintaining consistent moisture removal and minimizing surface damage, tunnel rolls contribute to the overall surface quality of the steel. This is especially important for industries that require smooth, defect-free surfaces, such as automotive, construction, or appliance manufacturing.

Increased Throughput: With tunnel rolls ensuring smooth and efficient movement through drying tunnels, steel mills can maintain higher throughput rates. The rolls help to streamline the drying process, reducing bottlenecks and allowing for a faster transition to the next phase in steel production.

Lower Operating Costs: The durability and low-maintenance design of modern tunnel rolls help reduce maintenance costs and downtime. Their efficiency in removing moisture also minimizes the risk of defects, reducing waste and rework that can be costly for the mill.

Improved Safety and Stability: By ensuring the steel moves smoothly and uniformly, tunnel rolls reduce the likelihood of misalignment, jamming, or other issues that could disrupt the production process. This contributes to a safer work environment by minimizing the risk of accidents or equipment failure.

Longer Equipment Life: Tunnel rolls are designed to withstand harsh environments, which means they can last longer and operate more reliably. This longevity reduces the frequency of replacements and contributes to a more cost-effective operation in the long run.

Thank you for considering us for your next alloy purchase.